Vibration Analysis

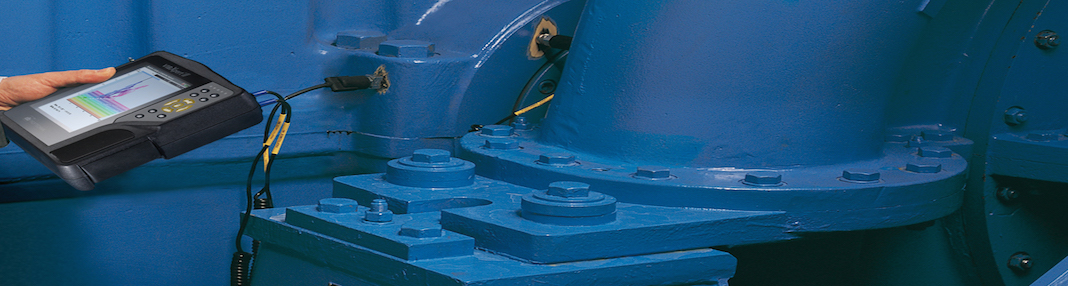

Vibration Analysis is a predictive maintenance method which allows early problem detection in rotating machinery, such as: Turbines, generators, mills, gearboxes, fans, shafts, motors, compressors, pumps, mixers, driers - in fact, almost any type of active machinery.

Vibration Analysis will identify component faults - such as defective bearings, Imbalance & misalignment and other defects which enable you to take maintenance action before a failure in service brings your plant to a halt.

ACMEI has 5+ ISO Level-III certified vibration analysts and 20+ ISO / ASNT vibration analysts. We are serving more than 60 customers with onsite AMC services and 300+ customers with visit based vibration analysis and correction services.

We have invested in advanced vibration instruments and related softwares coming from world leaders like Emerson, Pruftechnik, Azima DLI, OROS and VibroTek Russia.

We have multi channel vibration analyzer ranging from 32-channel, 16-channel, 8-channel, 4-channel and single channel instruments with built-in cross phase dynamic balancing and other advanced features to analyze basic equipment, high speed turbo machinery like compressors, steam turbines, multi-stage compressor, turbines, pumps, fans etc.

ACMEI Engineers are fully accredited in compliance with current H&S regulations and safe-working practice. Accreditations include ISO and ASTN, and are available for inspection on request.

ACMEI's vibration analysis services include

- Site visits for expert data collection & analysis

- Supply of data collection equipment and accessories

- Consultation on practical wireless remote monitoring solutions

- Design & Installation of hard-wired monitoring systems

Rotating Analysis

ACMEI enables rotating machinery measurement , with noise and vibration tests and analysis solutions.

From Acceptance Tests to Diagnostics

From Acceptance Tests to Diagnostics

Whatever the machine type: a high speed turbine, a compressor, a transmission or a slow speed engine, AC analyzers provide all the tools for rotating diagnostic and analysis, relying on rotating machinery testing.

|

|

|

Synchronous Order Analysis

Signals are resampled with a dedicated tachometer input to be converted to the order domain. Then the plug-in extracts complex orders (phase and amplitude). Order analysis and tracking techniques are essential in measurements with varying rotating speeds. Getting correct results from run-up/down requires specific signal processing techniques.

Constant Band Tracking

Gearboxes generate modulated and buried noise and vibrations orders, which are not easy to extract. Order analysis and tracking techniques are essential in measurements with varying rotating speeds. Getting correct results from run-up/down requires specific signal processing techniques.

Order Diagnostics Toolset

Order Diagnostics Toolset

The SOADiag software module provides innovative functions to track vibrations conducted/generated by the transmissions. This toolset allows rejecting the natural frequencies from the structure focusing on the ones propagated by gears, belts and shafts.The SOADiag software module provides an unrivalled investigation tool for measuring transmitted vibrations in rotating machineries for diagnostics and R&D purpose. Based on the OROS Synchronous Order Analysis, SOADiag supports super-fast speed variation machines like engines or motion motors.

Turbomachinery Vibration: ORBIGate

Orbit, gap, Bode, polar, half and full spectrum, run-out: all the tools for turbomachinery vibration measurements with a dedicated user interface. ORBIGate is the dedicated software module for industrial rotating machinery vibration during diagnostics as well as acceptance works. Easy to use, it provides all the tools to bring the highest level of set-up simplicity and efficiency to the user.

Reciprocating Machines Diagnostics, EngineDiag

Dedicated tool to analyze vibration on reciprocating machines (engines, reciprocating compressors, piston pumps) integrating the machines' kinematics. Integrate the machine mechanical properties and kinematics (number of cylinders, machine cycles, timing diagram) into NVGate, the Noise and Vibration software platform. The Advisor offers an easy software confi guration and results displays based on the machine characteristics and instrumentation.

Torsion & Twist

An Integrated Frequency to Voltage converter.

The Instantaneous angular Velocity Converter (IVC) provides instantaneous angular velocity signal. The Instantaneous angular Velocity Converter (IVC) provides instantaneous angular velocity signal to be analyzed.

Single, Dual & Multiplane Balancing

Dedicated to balancing, the module assists the user from the acquisition of the 1X (amplitude/phase) to the positioning of the correction masses: from the single/dual plane applications (rigid rotor) to the multiplane applications (flexible rotors). MVS ACMEI Balancing Solutions are software modules for balancing rigid and flexible rotors. These modules are well-suited for shop balancing or in-situ field balancing. They are designed to run on MVS ACMEI analyzers.

Spectral Diagnostics Toolset

Spectral Diagnostics Toolset

Going further in the diagnostic, the FFDiag software module provides a complete suite of diagnostic oriented functions. This toolset is adapted to steady state low speed variation machines. The FFTDiag software module enriches your NVGate FFT with powerful computations, graphs, markers and signal indicators. It offers a complete tool set for diagnostic purpose on steady-state or low speed variation machines.

Remote and Autonomous System for Temporary Monitoring (Satellite)

Systeo is a dedicated software for the temporary vibration monitoring of rotating machinery. Embedded in the ACMEI controller unit (SmartRouter), SysTeo becomes an autonomous monitoring system remotely from your office. With a 1 Gb/s Ethernet connection, OROS analyzers can be controlled through local network or internet. Thanks to the local processing and storage, the data bandwidth remains low, supporting wireless and low speed connection.

Multichannel analyzers

The 3-Series instruments are multichannel FFT analyzer, dynamic signal analyzer, FFT spectrum analyzer and portable vibration analyzer.Same platform, same technology, same software

Designed to be the best for field operations, the 3-Series instruments offer the capability of advanced laboratory instruments in a rugged and portable package that takes any measurement situation in its stride.

OR36, 16 ch. Teamwork Multianalyzer Recorder

Overview

Up to 16 channels, OR36 is a synthesis of components usually used separately for measurements: analyzer, recorder, conditioners in a single portable instrument.

With a comfortable computing power and its built-in Mobi-Disk, OR36 faces any measurement situation. It offers the capability of an advanced laboratory instrument in a modular, rugged and portable package.

Main Features

- Rugged 4 to 16 channels chassis

- Portable: 5.2 kg (11.4 lbs)

- Up to 40 kHz and 25.6 kHz bandwidths

- 4, 8, 12 or 16 universal inputs

- ± 40 V range, 24 bits

- Dynamic: AC/DC/ICP®/Float/TEDS

- Parametric: 10 S/s 50 Hz and 60 Hz rejection

- Support expander modules (Xpod) for strain gauges and thermocouples

- 2 to 6 triggers/tachometers - 2 to 6 generator outputs

- 1 Gb/s Ethernet PC connection, LAN, WAN and wireless

- AC/DC power supply + internal battery

- 1 to 4 real-time computation ForceDSPs

- Stand alone recorder (D-rec) with removable 128 GB SSD

ACMEI provide customers with a report that clearly and concisely presents the results of our vibration analysis surveys. We provide relevant information to maintenance personnel that not only indicates the ‘as is’ condition of your plant, but which also recommends areas for root-cause and process improvements.